Eplan in the process industry

- T.H.E. Machines

- Zahnen Technik

- Grundfos

- AuCom

- BRUGG Rittmeyer

- SGAC

“This is a considerable improvement for the development and production process, especially in the final phase of machine design, when “last minute” changes can occur.”

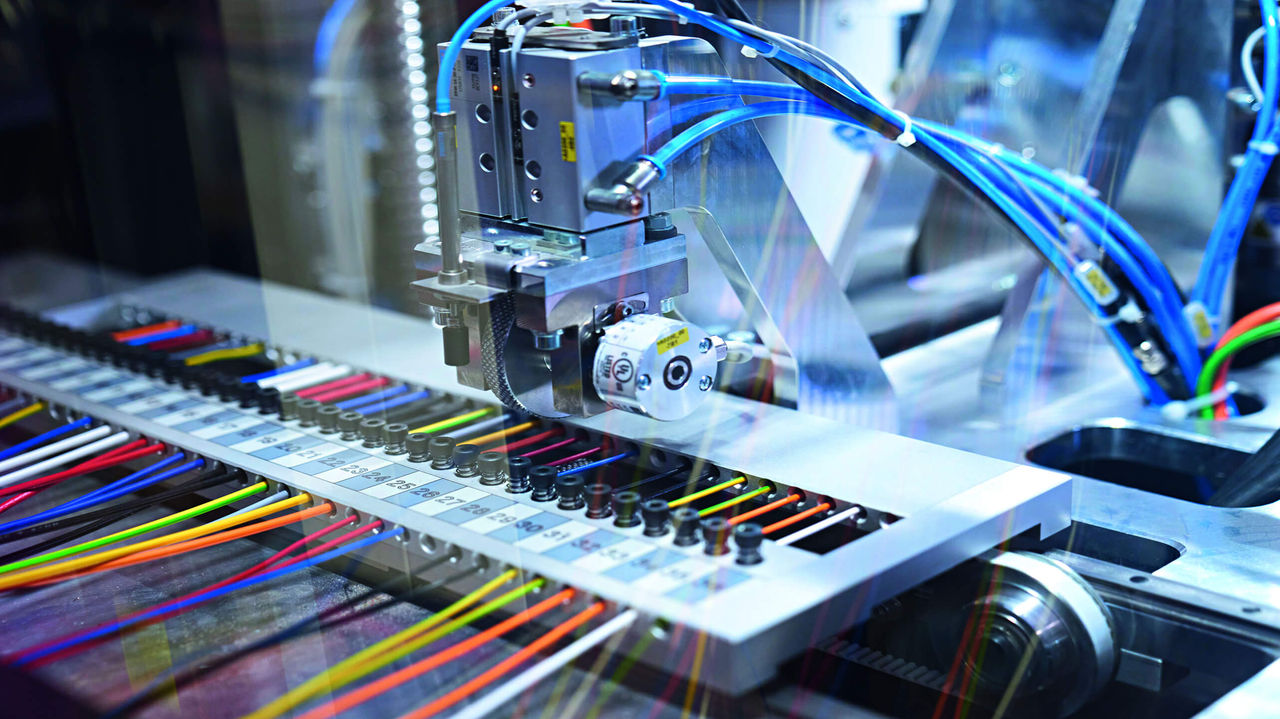

"We expect to reduce assembly times by 30 % once Smart [Production] has been comprehensively introduced."

"The Eplan Data Portal offers us a very good opportunity to make our component data available in a standardized way. The various users benefit from the high availability, quality of the data and more efficient processes."

Nine months to build and supply 400 switchgear units containing soft starters for electric motors for one of the biggest infrastructure projects in Egypt – imagine doing that just two years after launching your own panel-building operations.

“Eplan Electric P8 has meant a huge leap forward for us; we are certain we have put our faith in the right tool.”

„40% faster engineering with Eplan solutions.“

Your added value with Eplan in the process industry

- Data consistency

- Increased efficiency

- Integration

- Optimized communication

- Future-proof

- Standard-compliant engineering

Data consistency through a plant’s entire life cycle

Eplan enables centralized, structured data management for all engineering disciplines – from process and I&C technology to automation. The consistent documentation reduces error sources, increases planning security and ensures seamless collaboration across all project phases.

Great efficiency with standardized project planning

With Eplan, industry-specific engineering standards and predefined macros and templates can be used efficiently and modular engineering can be implemented. This standardization as the preliminary stage of modularization significantly shortens project durations, facilitates re-use of contents and increases productivity, particularly for plant configurations that repeat regularly.

Integration into IT and CAE system landscapes

The Eplan Platform can be seamlessly integrated into leading ERP, PLM and PDM systems. This creates a consistent, end-to-end digital ecosystem that avoids multiple entries and accelerates information flows between planning, procurement and operations.

Communication between planning, construction, operations

Thanks to web-based collaboration tools, project data can be shared with all project participants in real time. This promotes interdisciplinary cooperation, minimizes information loss and improves the basis for decision-making in all project phases.

Digital twin and modular design

Eplan supports the creation of digital twins as the basis for simulations, commissioning and later servicing. This offers decisive advantages for scalability and ease of maintenance, particularly in the process industry with modular plant structures (keyword: module type package, or MTP).

Remain competitive with standard-compliant engineering

With Eplan, companies rely on a platform that supports international standards (including IEC/ISO). This expedites global planning, which provides strategic advantages especially for plant manufacturers active around the world and operators in the process industry.

Would you like to find out more about our solutions or are you interested in our consulting services? Then please don’t hesitate to get in touch with us – we’re here for you!