Digitalization is key – and possible with Eplan

Our approach to meeting the challenges facing the construction industry is therefore more digitalization, but not as an end unto itself or even to add additional hurdles. Instead, our software is a sophisticated solution to improve interactions between building planners, building system integrators and building operators. That’s because what we are providing is an integrated and consistent data platform. Thanks to standardized exchange formats, it can easily be well integrated into existing IT infrastructure. This enables the many parties involved with building technology to reach a common understanding.

The final goal is consistently in focus from the very start when using our solutions. In other words, we emphasize the credo “planning to operate.” For instance, we provide templates for specifications that facility managers and site managers can use to determine early on in the process what information they will need later during building operations, which are available at the appropriate level of detail. We achieve this by relying on technical, graphical and commercial device data. This and smart configurators make coordination processes faster and more reliable. You can rely on this because working with consistent and integrated data is nothing new to us, it is now and always has been how we do business.

BIM in construction: data available

For planning using the methodology of building information modelling – or BIM for short – consistent, standardised alphanumerical and graphical data must be available for documentation. With Eplan, data from the electrical engineering designs can be used for this purpose. Information and data – including for instance about the site itself, buildings and rooms – is transferred from a 3D BIM model to the Eplan Platform. In addition to this, data from components including sensors and actuators can be imported to help generate the schematics. With our involvement in the “electrical domain” of buildingSMART International, we are advancing the integration of our solutions in the application of the BIM methodology.

Eplan in the construction sector

Read here about who in the industry relies on our solutions and how they increase their efficiency in planning building technology.

- Kreutzpointner

- EliteBuildingArchiTec

- EWR

- G. Klampfer

- AL-KO Therm

- Neuberger

“We wanted to use not just the most convenient, but basically the best system for the job.”

“In building planning, there is a lot of chatter about the digital twin. We implemented it a long time ago.“

“You could even say that Eplan has made a significant contribution to our high market position in plant project planning!“

Automated engineering with solutions from Eplan leads to massive time savings while at the same time significantly increasing the quality of the documentation.

"I&C engineering used to slow down our design processes. It is now not only faster but we can also depend on it being free of errors."

“By using Eplan, we have achieved an increase in quality, which subsequently reduces costs.”

Automation is essential

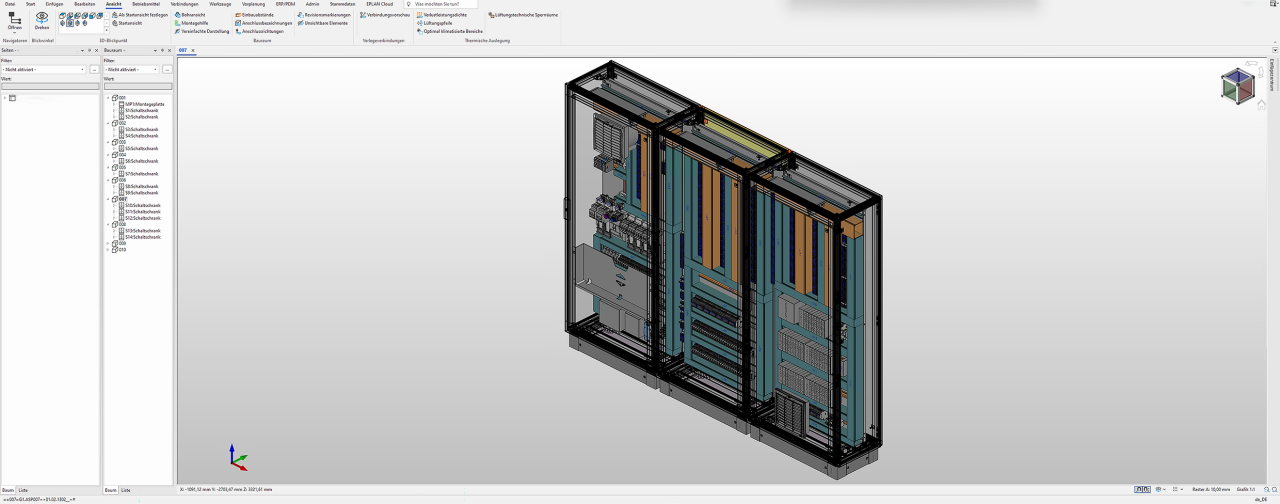

Our solutions for building technology aim to assist in the optimal planning, building and operating of systems for the generation, distribution and storage of electrical energy. Building automation is also realized in this process – meaning the interactions of the systems, including energy management. Building automation is the key to realizing efficiency and sustainability requirements and requires the use of actuators, sensors, cables, control systems and control cabinets – just as is the case in industrial automation, the field in which our business rose to prominence.

In the engineering process, a system overview with individual system components and electrical loads is first created. The required functions and necessary sensors and actuators are then defined in the automation diagrams. The data collected here is the foundation for the electrical engineering planning, meaning the building automation is included from the very start.

Our solutions meet the common requirements clients have for planners and system integrators. They are based on common standards and guidelines including DIN EN ISO 16484-3, VDI 3814 from the Association of German Engineers, and also AMEV BACtwin for building automation.

Building technology value chain digitally mapped

Eplan provides the right tools for consistently planning building technology for all service phases and for being able to access all relevant data during operations. This means that redundancies and media disruptions are avoided – thereby reducing the amount of additional work and the number of sources for errors.

System integrations are made easier due to the standardized, consistent and integrated use of data. Communication is also accelerated: thanks to the digital networking of all project stakeholders, everyone has access to the same data foundation and can effectively exchange information. The complexity of subtasks can also be reduced in this way. Last but not least, building operations and maintenance run more smoothly with the fast access to data that is always up to date.

The data is consistent – benefitting every single phase of the process. Click on the graphic to see the specific advantages for the individual steps.

Eplan’s added values in building technology

- Better coordination

- Consistent data

- Broader view

- Building Information Modeling

- Saving resources

- Reduce complexity

Clear information requirements

In some projects, communication simply does not run smoothly because it isn’t clear who needs which information at what time. For instance, it can happen that those responsible for the technical building equipment involve the electrical design engineers too late in the process – which results in changes, adjustments and costs increases. In contrast, using Eplan means that the dependencies become visible earlier in the process, enabling communication and information exchange throughout.

Efficient system integrations

The Eplan philosophy is based on the consistent use of data. To achieve this, we rely on standardized interfaces, thereby preventing media disruptions and data redundancies. This also simplifies approval processes since all project participants – including planners, OEMs, system integrators and control cabinet manufacturers – can store the testing procedures and approvals using Eplan cloud technologies in one and the same project. Comments and changes are transparent to everyone.

Data for downstream phases

As the system integrator, you keep an eye on the big picture. The key question is how you can use the information from the planning of the building for programming the building management system. With the Eplan Platform, you have the required data at your fingertips. We rely on technology partnerships and provide the appropriate interfaces.

Integration into the BIM methodology

Eplan is used to synchronize data from the BIM model and the functional description of systems and components: the functional descriptions are created for the planned components in the model – for instance in form of diagrams and schematics. The component data, which originates in the BIM model, is expanded to include electrical engineering data and automation data. Data packages enhanced in this way are then fed back into the BIM model.

Buildings are operated economically

Various data formats in engineering, plans printed on paper, differing designations and project structures – the lists of obstacles to efficiency is long. Not to mention that documentation for the many systems is sometimes not readily available. In contrast, using cloud services means that up-to-date data is always accessible, making service and maintenance far more efficient overall. Using Eplan as a consistent platform means that the necessary data can be read in and out in a structured way.

Overcoming the shortage of skilled labor

Eplan helps reduce the complexity of individual tasks. The software supports completing these tasks, which can then also be carried out by personnel without in-depth specialist knowledge. It goes faster based on standards and templates. Standardization is the foundation for semi-automated and automated engineering. The Eplan Platform and Eplan Consulting can help you make it happen.

Clever project planning with Eplan Industry Standard Projects

Would you like to find out more about our solutions or services? Then contact us – we’re here for you!