Your workflow

- Your challenge

- Our solution

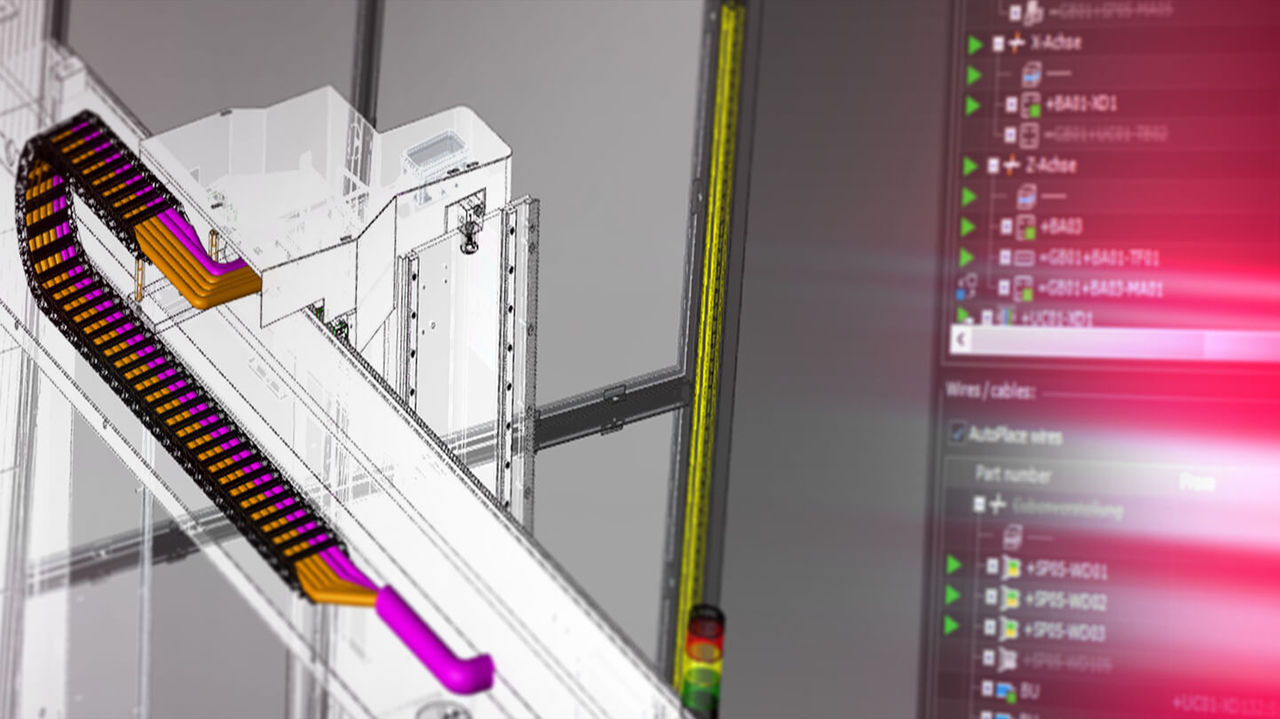

Digital Twin of the machine cabling

Advantages for planning

- Plan and visualise cable routing, drill holes and punchouts

- Determine cable lengths during the planning process

- Order prefabricated cables from the manufacturer long before they will be installed

- Define clear specifications for assembly and clearly depict them

Advantages for assembly

- 3D model available as a digital prototype for standardised cabling

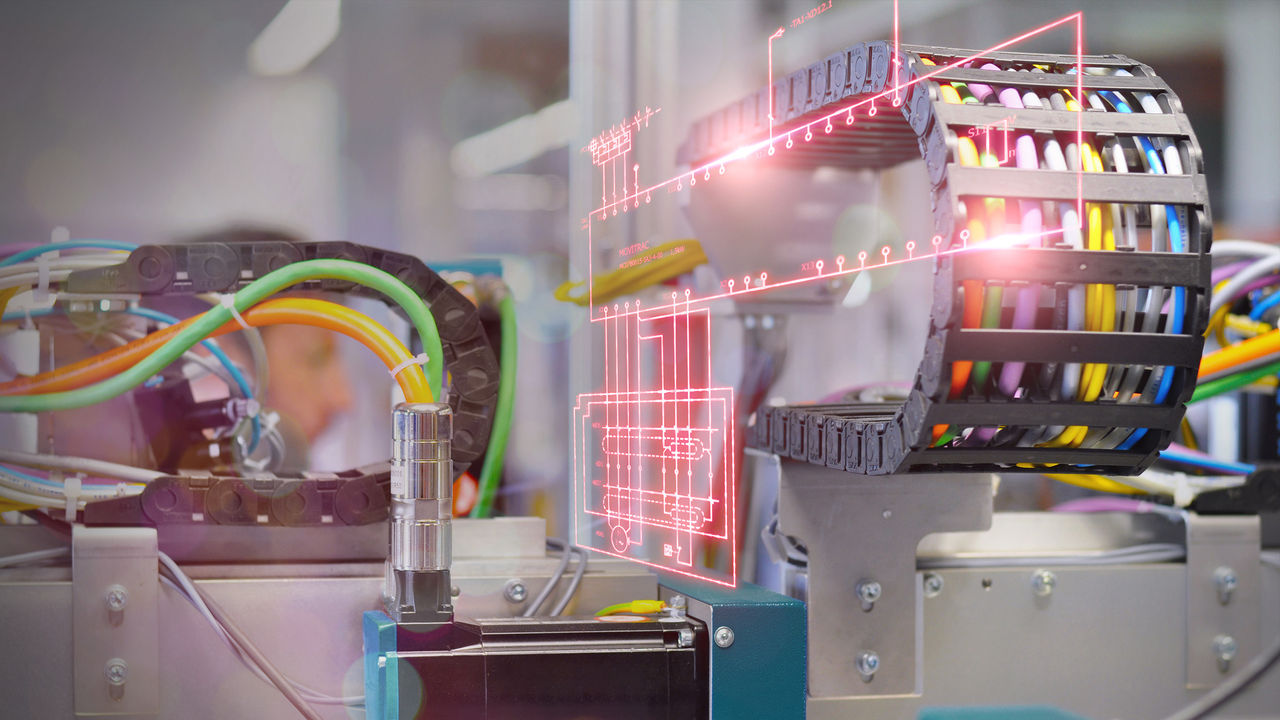

- Prefabricated cables can easily be connected

- Trouble-free assembly and customer approval

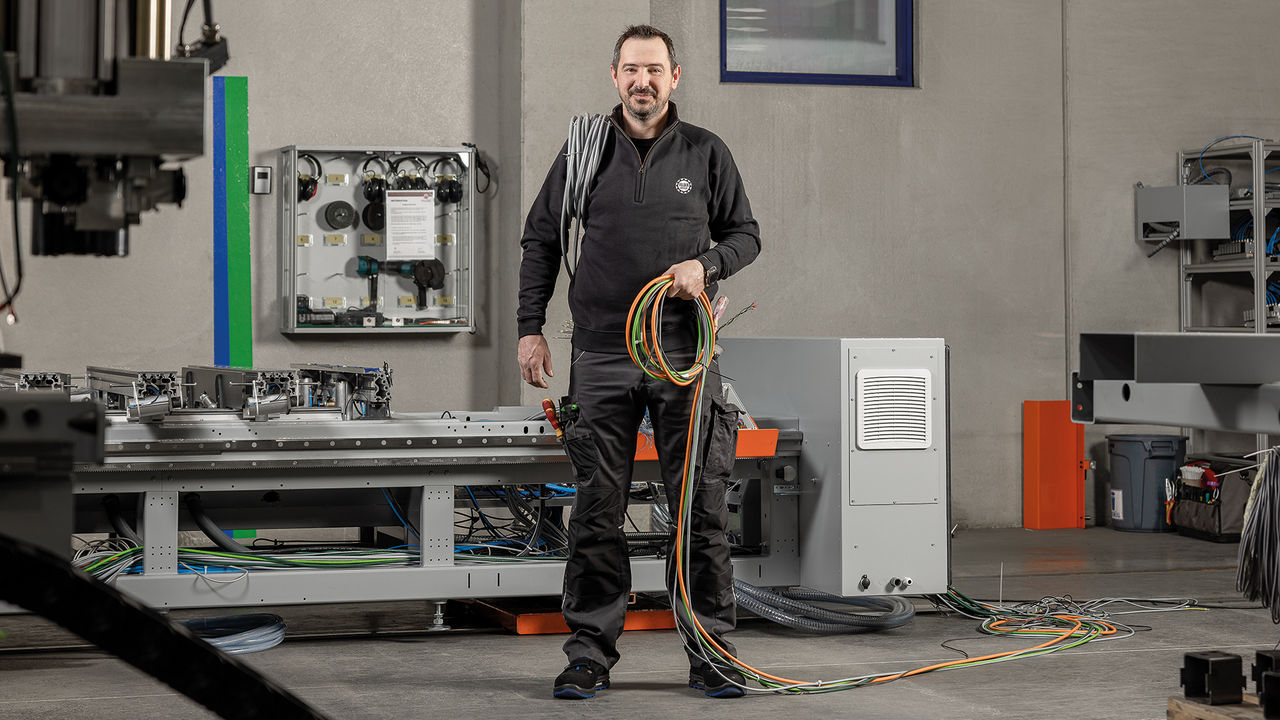

- Reduced material consumption reduces production costs

That's how our customers in machine building benefit from working with Eplan

- psb intralogistics

- Hahn Automation

- Felder Group

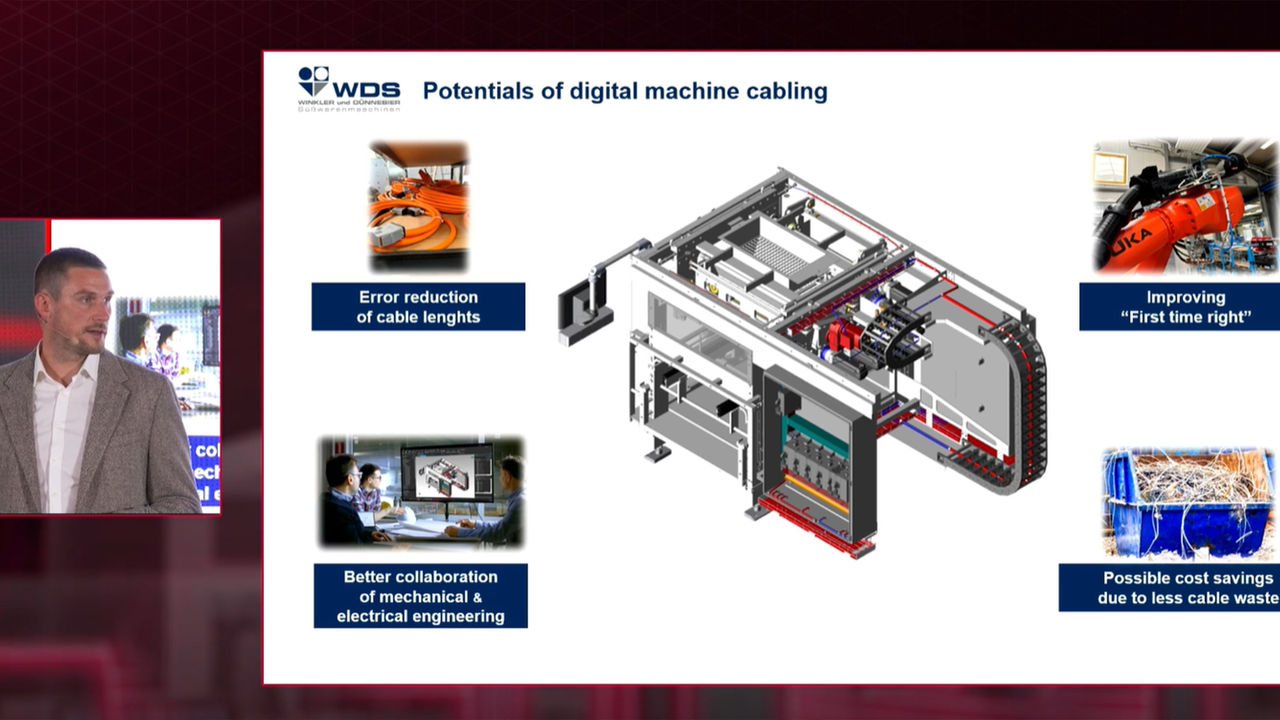

- Winkler und Dünnebier

"By precisely determining the cable lengths and providing detailed documentation, we save costs and avoid additional design time. Ordering the right cables reduces unnecessary waste and enables immediate installation."

"The system reliably determines the cable lengths, so you don’t have to measure beforehand or make corrections after the fact. And our technicians can work quickly without making any mistakes because the routing paths are displayed in the viewer."

20 % shorter development process for electrical design with Eplan Cable proD.

“First time right, i.e. the quantity of cables is increased where the cable length is right the first time and not second time still wrong.”

- Increased productivity

- Digital twin for cabling

Would you like to find out more about Eplan’s software and services? We’re happy to help!