Eplan in the automotive industry

- Suncar

"The intuitive 3D environment of the Harness proD tool in particular makes it much easier for us to design the wiring for vehicles and machines.”

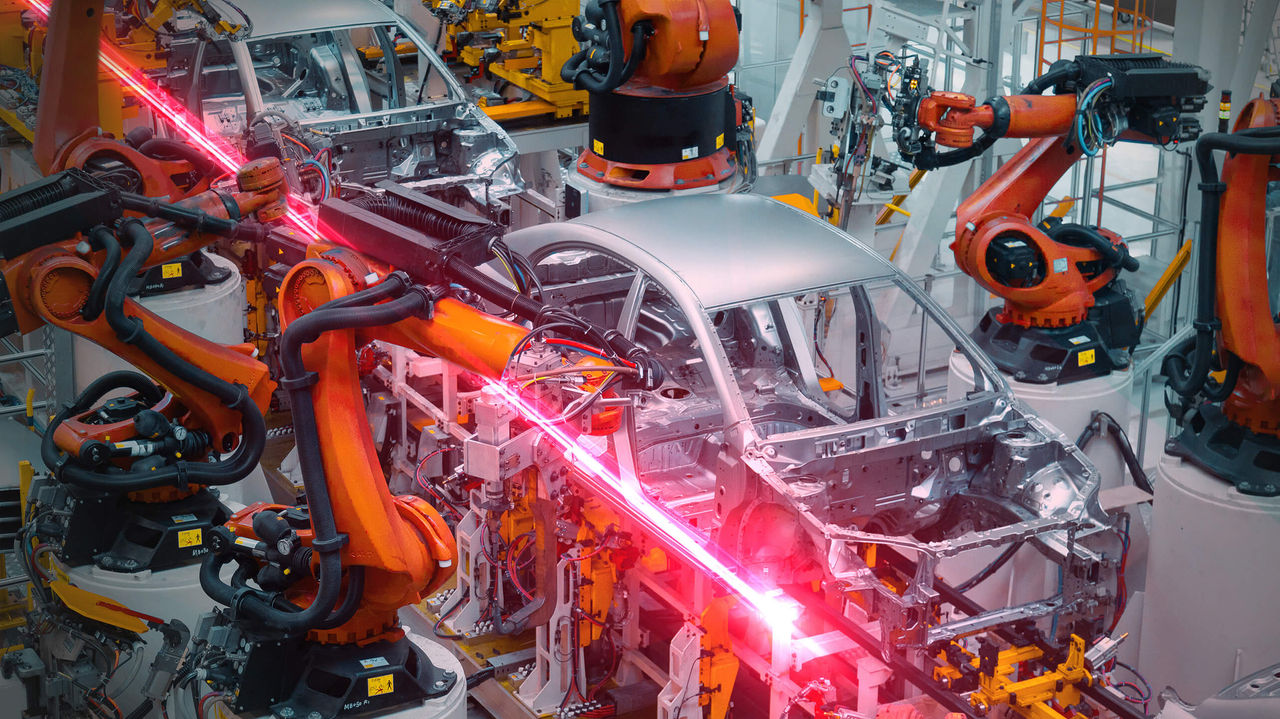

A consistent standard for the entire supply chain

In the automotive industry, the smooth interplay between OEMs and suppliers in the areas of plant, machine and control cabinet production is critical.

As an Eplan user, you benefit from integrated, end-to-end solutions throughout the entire engineering process – from the concept phase to standardization and detail engineering to manufacturing integration and complete, automatic plant system documentation.

Whether in the press shop, paint shop, body shop or on the assembly line: Eplan supports you with structured planning and project management of complex automation systems. The documentation automatically generated in this process forms the foundation for trouble-free plant operations and efficient maintenance and repair processes – always transparent, up-to-date and usable across all systems at all times.

Your added value with Eplan in the automotive industry

- Consistency

- Scalability

- Standardization

- Process integration

- Efficiency

- Future-proof

Networked engineering across all disciplines

Eplan unifies a variety of engineering disciplines including electrical engineering and fluid power engineering, wire harness design, and building automation on an integrated platform with a uniform data foundation. This reduces interfaces, helps prevent mistakes and increases the design quality across the entire product development process.

Scalable solutions for every company size

Whether locally or worldwide – Eplan can be scaled flexibly. Automotive groups rely on centralized templates and macro libraries to establish consistent engineering standards around the globe.

Modularization and designing to comply with standards

Consistent standardization and the re-use of modules help to reduce development times and enable the efficient implementation of platform concepts – even for model variants and vehicles produced in series.

Seamless integration into ERP, PDM and MES Systems

With Eplan, engineering data can reliably be integrated into company processes. The things this makes possible include the automatic creation of bills of materials for commercial processes, transparent change tracking, and secure documentation and product data management processes.

Eplan enables standardized engineering

Eplan enables standardized and automated engineering for automation technology with schematics and/or project templates and pre-defined global data standards. The high level of automation depth reduces routine work and significantly accelerates project creation.

Digital twin for manufacturing and maintenance

Eplan gives you a digital foundation for manufacturing, conversion and operation of your plant systems in production facilities – including simulations, maintenance and retrofitting. It is ideal for Industry 4.0 strategies in the automotive environment.

Our products and solutions help standardize and automate engineering and manufacturing processes.

Would you like to find out more about our solutions or are you interested in our consulting services? Then please don’t hesitate to get in touch with us – we’re here for you!