Standardized processes for efficient engineering

A U.S.-based control panel manufacturer reduced total project time—including design and assembly—by 59% and eliminated workforce scalability barriers by adopting modular engineering software and production automation. The implementation significantly streamlined lean processes and improved overall throughput.

Founded in 2011, Automated Drive Systems, LLC (ADS) is a high-tech distributor and manufacturer of custom control systems. Based in Omaha, Nebraska, ADS provides panel manufacturing and process automation services for AC/DC drive systems and PLC-based control architectures. The company employs approximately 18 people.

Business need

Like many in the panel building industry, ADS faced persistent challenges in hiring and training skilled technical staff. Engineering tasks such as schematic creation and bill of materials generation typically require experienced personnel. These deliverables are often passed to assembly teams—an approach that can introduce inefficiencies and variations.

From the beginning, ADS needed to optimize its operations to become less dependent on expert-level staff and more scalable. The objective was clear: standardize engineering processes to streamline onboarding and increase efficiency. This standardization enabled ADS to automate two labor-intensive processes by introducing a wire processing machine and a CNC enclosure modification system.

To fully integrate these systems, ADS required a solution that could standardize schematic and layout creation and deliver accurate manufacturing data directly to the shopfloor. That need led them to the Eplan software ecosystem.

Solution implementation

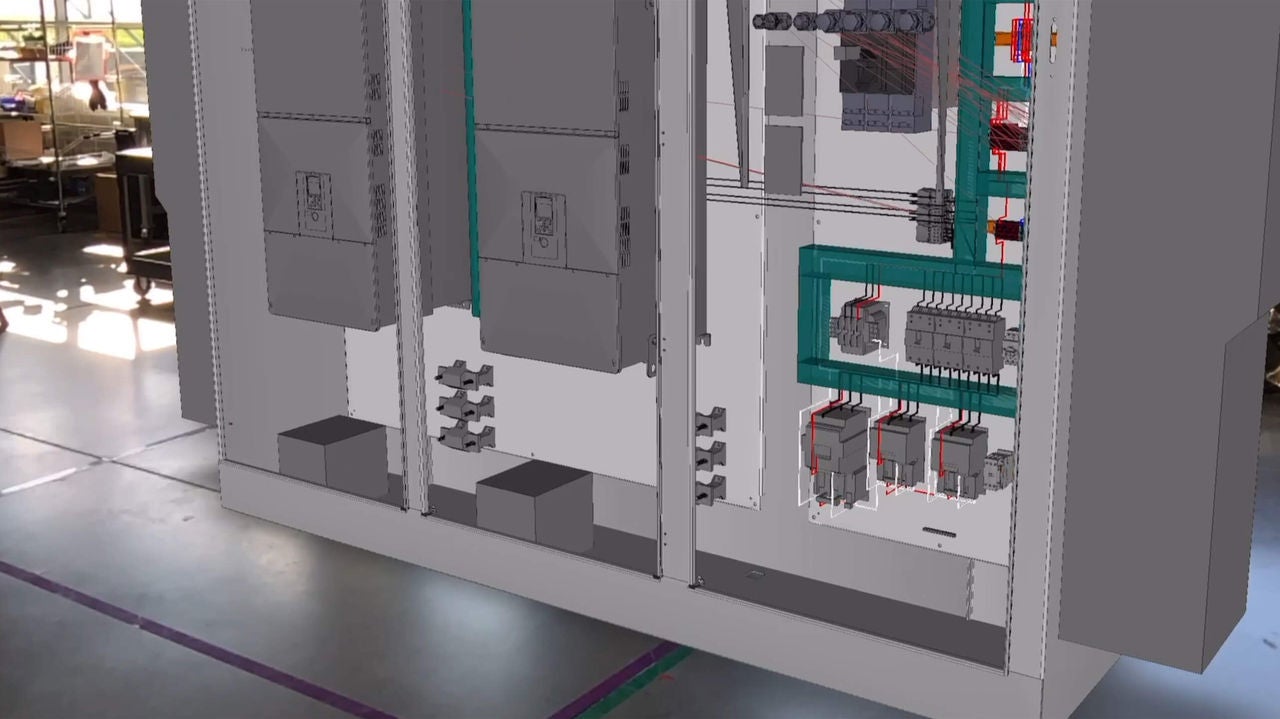

ADS selected Pro Panel to manage electrical design and 3D control cabinet layout. The software allows users to create modular circuit macros, automate wiring documentation, and integrate data with other toolchains. Engineering data is sourced directly from the Data Portal, ensuring standardized, manufacturer-compliant parts selection and automatic bill of materials generation.

To support visual collaboration, ADS uses Project viewer – eView. This module enables technicians and project stakeholders to interact with digital twins of control cabinets and visualize project status in real time.

The digital twin—a virtual 3D model of the cabinet—allows users to validate spatial layouts and configurations before initiating physical builds.

Augmented reality & continuous feedback

The Project viewer also supports augmented reality (AR), allowing users to overlay 3D cabinet models into real environments for physical review. Technicians can navigate from the virtual cabinet to specific schematic symbols and receive contextual information for better decision-making.

Engineers, service teams, and customers can annotate projects directly within the viewer interface, ensuring that documentation stays current through the lifecycle.

Collaboration and scalable manufacturing

To facilitate cross-location data sharing and internal collaboration, ADS uses Data management – eManage. This cloud-based solution provides centralized access to project data, version control, and change tracking between stakeholders.

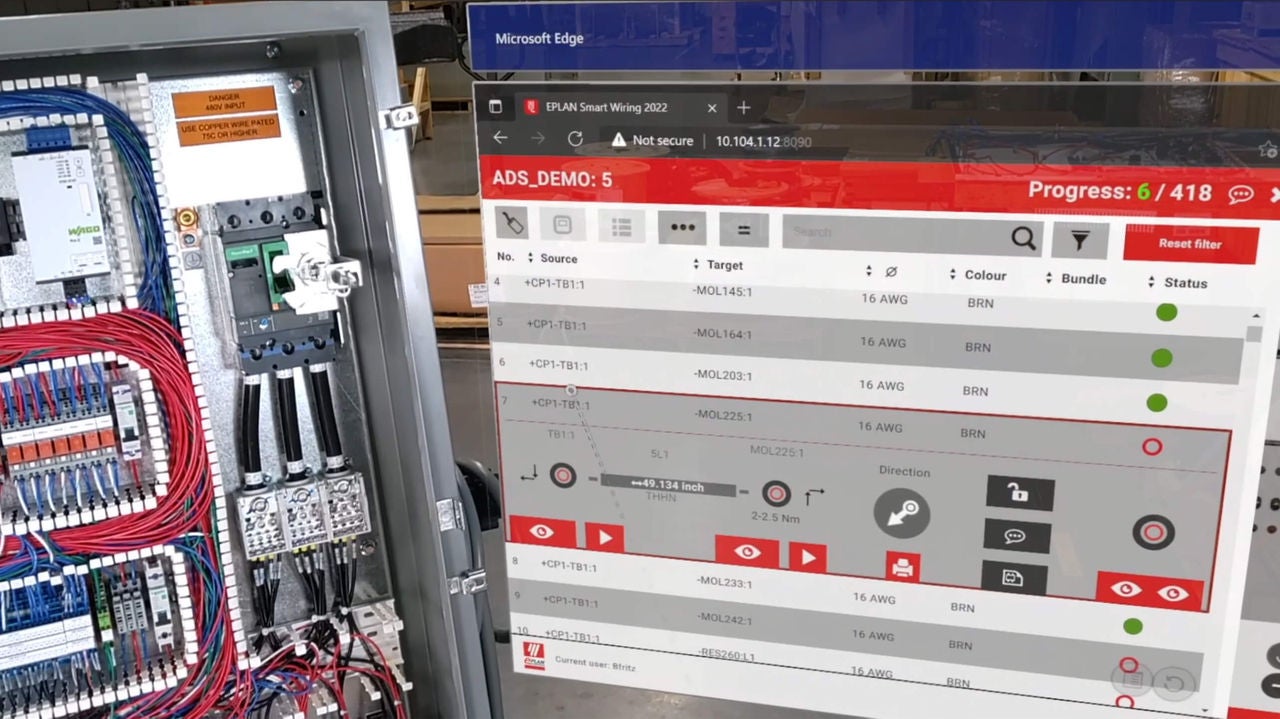

For guided wiring on the shopfloor, ADS implemented the wiring module of Eplan Smart Production. This module presents digital, step-by-step wiring instructions, reducing reliance on expert assemblers. The company adopted a cell-based production strategy, where tasks such as door wiring, cabinet assembly, and testing are handled in dedicated work cells.

For instance, one technician wires panel doors while wearing an AR headset and using the wiring module, while another performs testing in a parallel cell. Updates made through the Project viewer are automatically reflected in the wiring workflow, ensuring complete alignment between engineering and execution.

Benefits

ADS achieved a 59% reduction in project lead time, from initial design through final assembly. Documentation and revision control also improved significantly.

The company scaled its workforce from five to 18 employees within three years—an achievement made possible by modular processes and guided wiring. New hires with limited experience can become productive within two weeks.

Automated documentation also improved the accuracy of bill of materials, supporting ERP integration and increasing the number of wire terminations completed per hour.

By combining software-driven engineering, digital collaboration, and automation-ready output, ADS enhanced its lean processes and elevated customer experience—transforming its operation into a model for scalable, efficient panel manufacturing.