BOMAG standardises the electrical design of mobile machinery

The goal for the BOMAG electric engineers was clear: to accelerate wire harness development and manufacturing. The complex wire harnesses also needed to be available at the same time as the actual mechanical prototype of the machine. One of the things that helped them achieve this was the combination of Eplan Electric P8, Eplan Harness proD and a well-equipped wire harness prototype construction facility. The digital twin of the wire harness is simultaneously used in mass production and when communicating with third-party manufacturers.

The final step, traditionally, is to bring in the electrical engineer – a convention that still holds true for prototype production in many mechanical engineering companies. It isn’t until the mechanical design is (almost) completed that the electrical engineering team can begin taking measurements for the wire harnesses.

Designing with the digital twin – from the very start

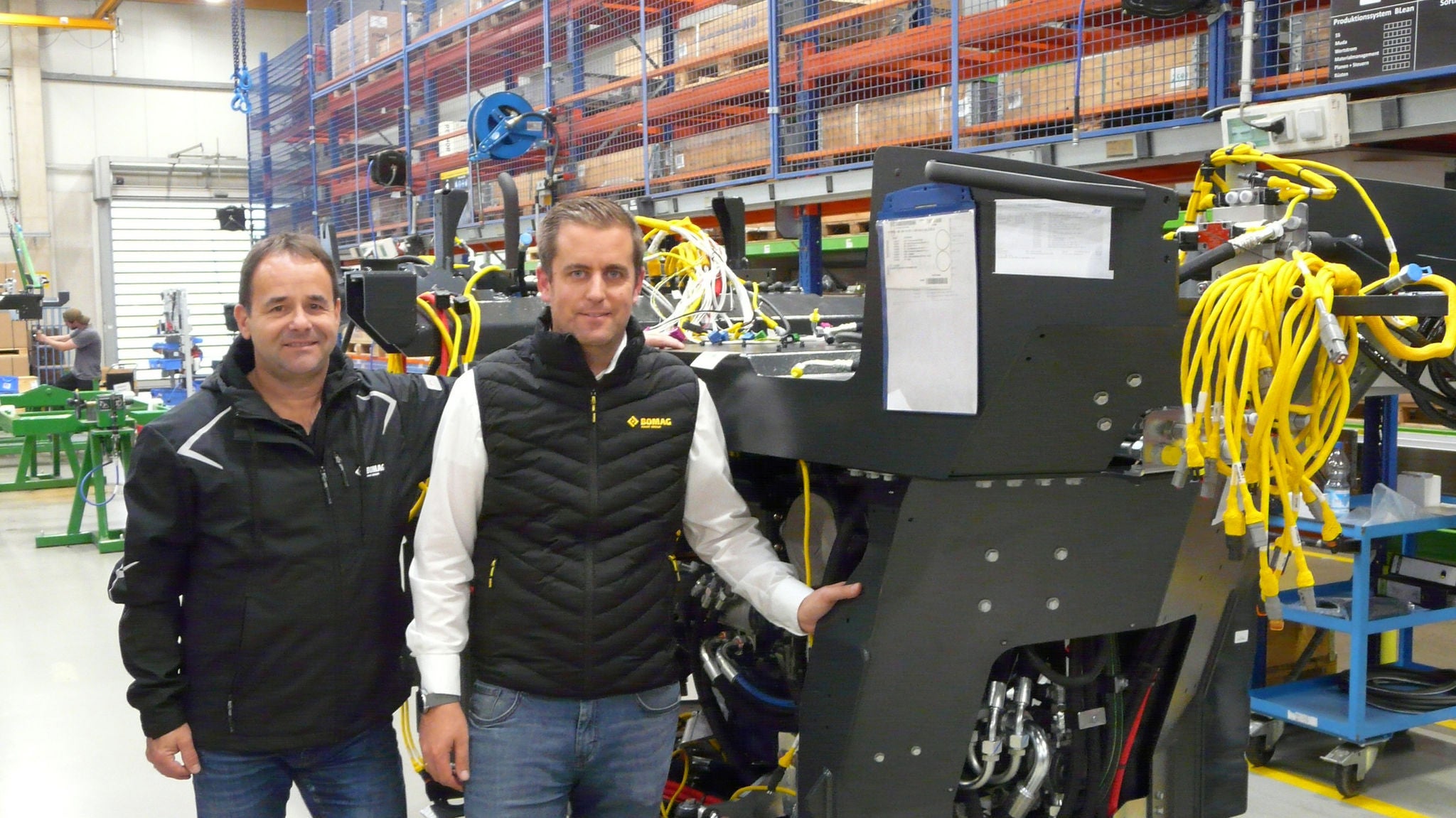

The company BOMAG, the world’s leading manufacturer of soil compactors and asphalt rollers as well as asphalt distributors, pavers and feeders (see boxes 1 and 2), was one of the first companies to focus on parallelising its development steps. When developing new machines, the electrical designers work with a digital twin right from the very start and can use the twin and its data both in prototype production and throughout the machine’s entire production process.

This parallelisation process began about ten years ago with prototype construction. Sascha Michalski, a BOMAG trainee at the time and now the company’s electrical engineering team leader, was part of an in-house project evaluating three-dimensional wire harness design. The challenge was identified by the electrical engineering department itself: “It was just annoying and inefficient for us to measure the mechanical prototype in a kind of reverse engineering, then ‘design’ and manufacture the wire harness, all under considerable time pressure. Our goal was to have a drawing of the associated wire harnesses, or even better, to have the actual wire harnesses on the laying board near-ready for mass production, all before the physical prototype was completed.”

One machine – around a thousand individual cables with a total length of more than two kilometres

Sascha Michalski illustrates the challenge that this goal poses with an example: “A BW 174 AP-5 AM asphalt roller with a hybrid diesel-hydraulic drivetrain has around a thousand individual cables installed in it with a total length measuring more than two kilometres – and that’s just the basic machine. The length of all the cables can increase by 30 to 40 per cent depending on the options the customer selects.”

Eplan Harness proD changes working methods

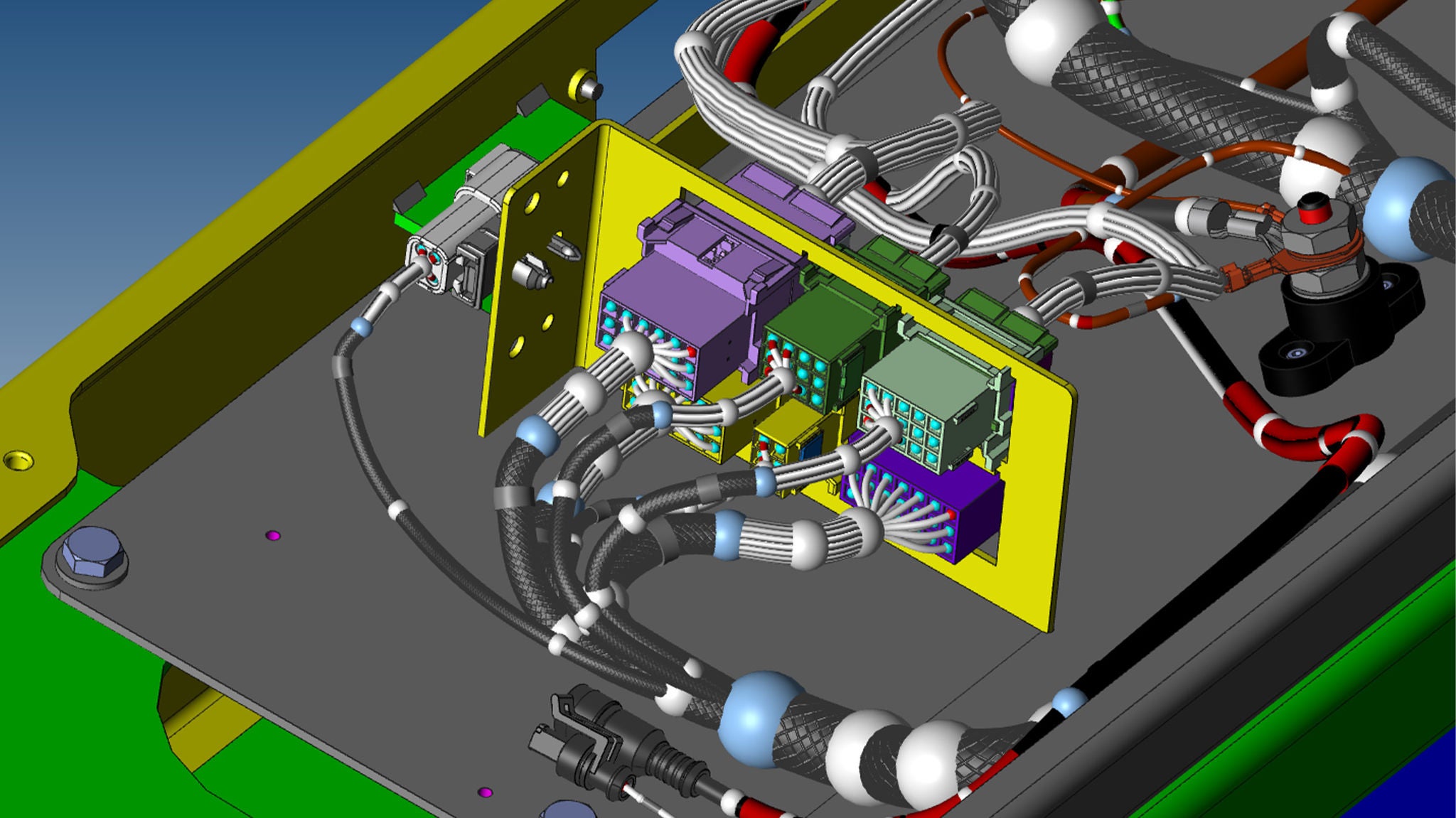

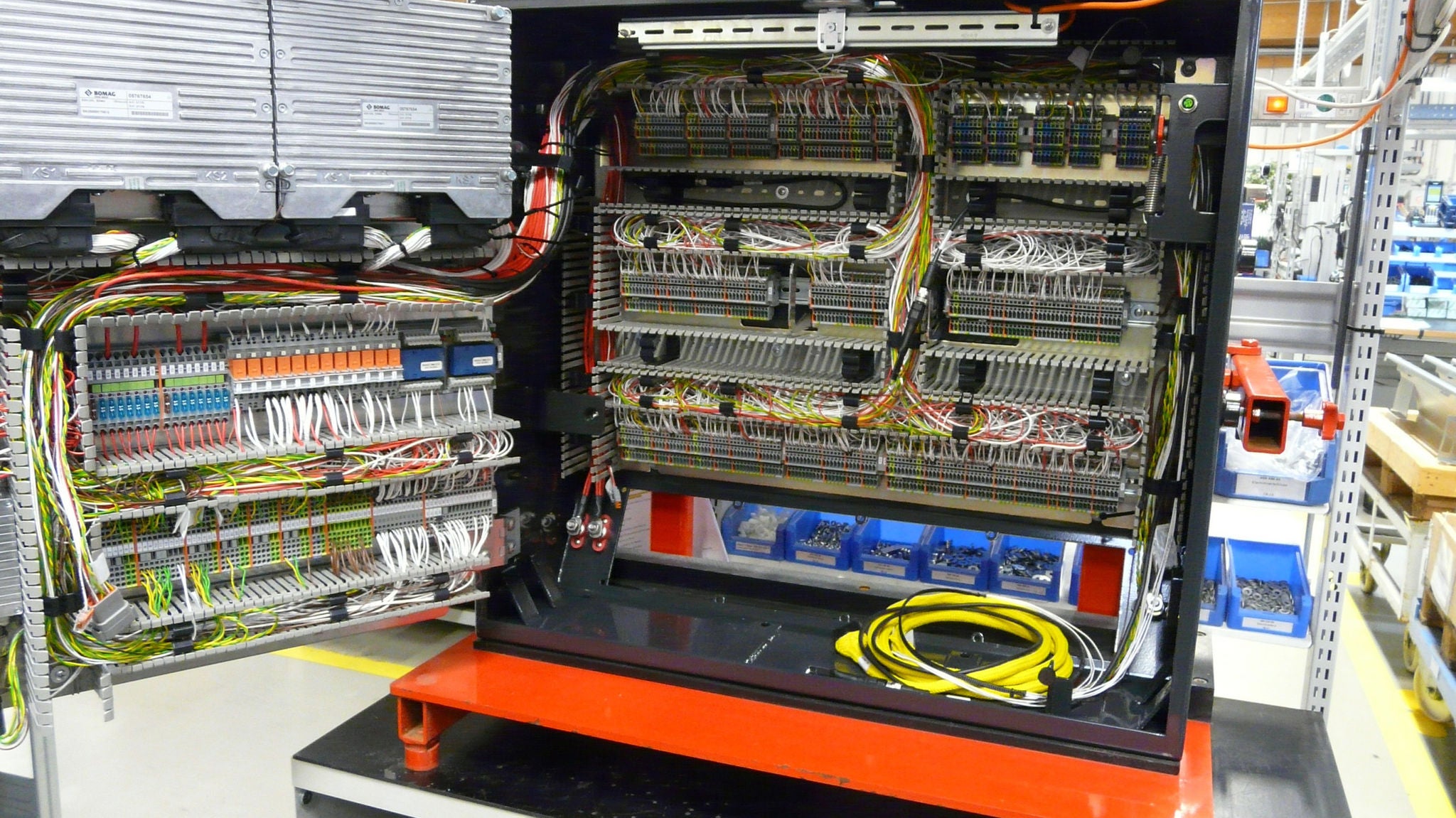

It quickly became clear that Eplan Harness proD was the right tool for the job. The software has an extensive database that enables the automatic determination of bills of materials and the creation of detailed wire harness drawings. The user-friendly interface quickly delivered initial results and was easy to introduce and implement since the company was already working with Eplan Electric P8. Harness proD can also be used to create complex wire harnesses using the CAD data from mechanical engineering designs – including all the routing paths and fasteners. This means that mechanical engineering and electrical engineering can work in parallel, which not only saves time, but also facilitates fine-tuning and provides clear specifications in the first step of prototype construction, for which the BOMAG electrical engineering department is well equipped; even complex wire harnesses are prepared in-house, built on a laying board and comprehensively tested. This optimised process now also offers BOMAG the opportunity to work with third-party manufacturers for the prototypes.

More than 30 prototypes each year – and 300 to 400 new wire harnesses

Sascha Michalski’s perspective demonstrates the importance of both automation and standardisation in the field of prototype construction: “In 2026, we will be responsible for the electrical engineering and wire harness production of more than thirty prototype models – from hand-held machines to complex planers and rollers. A total of 300 to 400 new wire harnesses will then be added to our active inventory of around 2,000.”

It should also be noted that the department is also responsible for maintaining not only the wire harnesses, but also further electronic components including lighting and power boards of the machines the company has already sold. From the company headquarters in Hunsrück, located in the Rhine Gorge just south of Koblenz, they also support their coworkers at other company sites – in China, India, Italy and the US – where their tasks include country-specific design adjustments. Sascha Michalski: “Over the past few years, we’ve been training additional employees, both at our headquarters and in India and China, to work with Eplan Electric P8 and Harness proD. We’ve also been successively increasing our capacities in the US and Italy. By now we have more than thirty Eplan users worldwide, including users working with Eplan Fluid Power Engineering.”

From prototyping to mass production

After Eplan Harness proD was introduced into BOMAG’s prototype construction a good ten years ago, the routing tool quickly became the standard for the company’s mass production as well. One of the many features the design engineers utilise is the connection from the Eplan schematics to the 3D model, while a comprehensive database running in the background compiles the required components for the wire harness, such as fasteners.

In addition, BOMAG can generate drawings with in-depth information from the 3D model in Harness proD, providing end-to-end consistency between the 3D model, the database and drawings, all based on the Eplan Platform. Moreover, according to Sascha Michalski, Eplan has proven to be very user-friendly; he describes it as “a system by electrical engineers for electrical engineers.”

Data for outside cable assembly

While BOMAG assembles the wire harnesses for the prototypes in their own well-appointed workshop, the mass-production ones are assembled by outside suppliers. So far, these suppliers have not received any actual prototype harnesses, but rather the data derived from them. Standardisation is another advantage here. Electrical Lead Engineer Thomas Seis explains: “The wire harnesses for the individual models and model variants are not customised, and we try to get by with as few part numbers as possible. This simplifies production, even as it makes designing more complex.”

At the same time, the BOMAG electrical engineers also work with Eplan Harness proD when making changes to current products. Sascha Michalski: “Maintaining the current products is much more time-consuming than prototype construction. This is because implementation times are often significantly shorter, and a physical prototype is usually only available to a limited extent. Overall, there is a wide range of tasks involved, and Harness proD immensely simplifies the work for us. We can discuss things with the mechanical engineers on an equal basis, and both sides know where and how much space is available for cables or hoses, for example.”

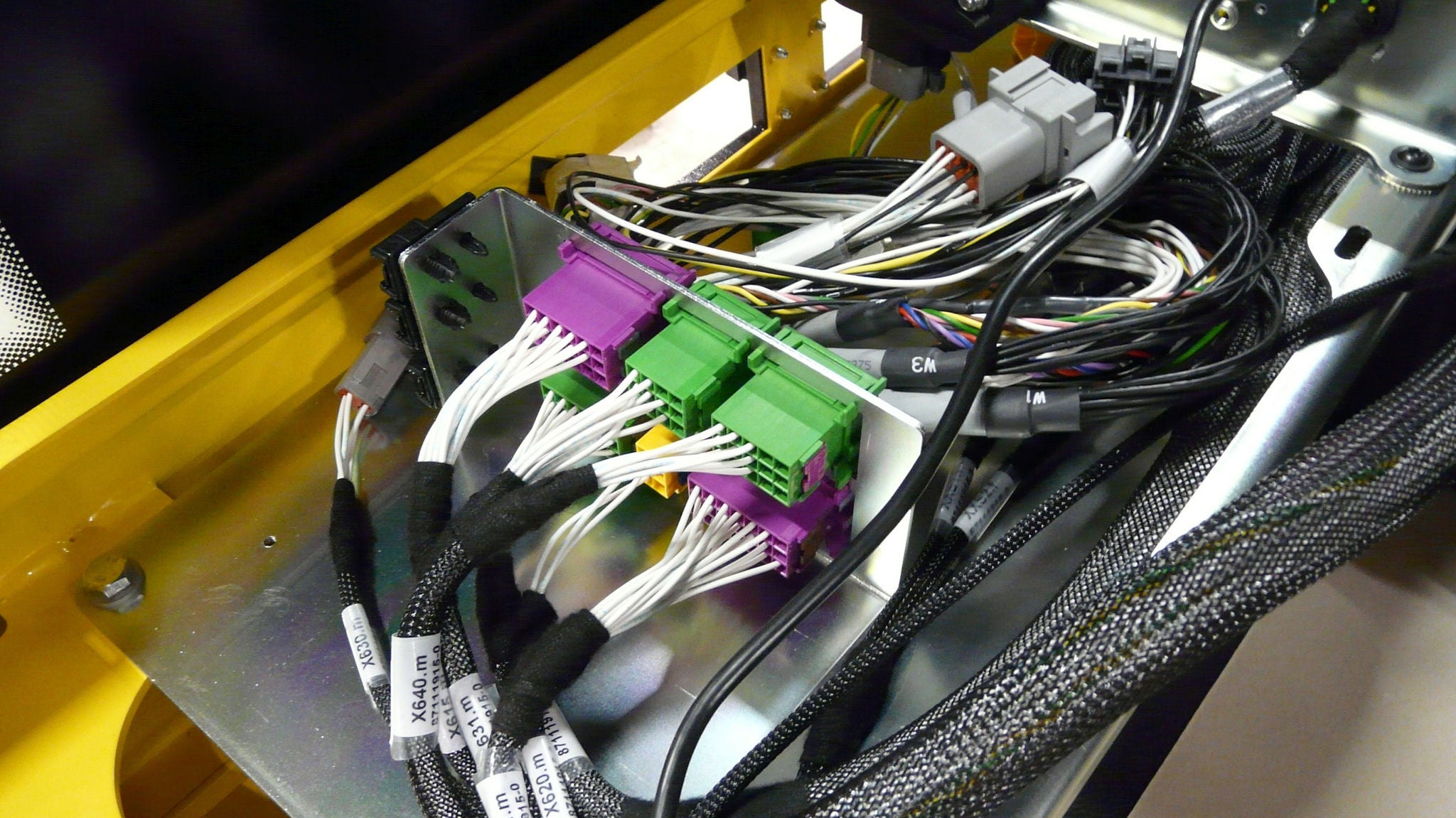

The advantages this offers become clear when you look inside, say, an asphalt roller: the “packaging” is extremely dense and that isn’t going to change. In fact, the opposite is more likely: the number of cables is constantly rising. Increasing numbers of functions are triggered electrically or electronically. Sensors are required for automatic functions, there are more and more assistance systems, including the remote control of machinery, and the various camera systems are connected to Ethernet networks.

In-house database with nearly 8,000 individual parts for wire harnesses

Sascha Michalski quotes a few figures to showcase the complexity of wire harness development and production – and how important consistent, platform-based standardisation is: “Around two hundred different components are required to manufacture a single engine wire harness: cables, connectors, seals, caps, connector holders, cable protection systems, etc. We’ve set up our own Eplan database for such components, which we continue to maintain. For the cable harnesses alone, there are currently almost 8,000 individual parts stored in it.”

The consistent use of Eplan Harness proD is worth the effort for several reasons. For one, the data is so accurate that BOMAG can have even the most complex wire harnesses manufactured by several different suppliers because the quality is always identical. Thomas Seis: “The manufacturer just has to follow the drawings, then they can’t go wrong. We can be flexible with our suppliers because we also have the expertise for the hands-on work in-house, like re-braiding the cables, and the drawings are very precise.”

Project Options: all data on a single platform – worldwide

With electrical design engineers at five company locations, this now means that CAD systems are becoming increasingly networked. All the sites are equipped with Eplan Electric P8 and Harness proD. New generations of machines continue to be developed in Boppard, Germany, but employees outside of Germany take on tasks that include localising the designs with other engine variants or country-specific functions and requirements. They have live access to inventory data from Boppard from the start. Sascha Michalski: “In this case we work with ‘Project Options’ from Eplan, which allows us to have the data for a model with all the engine variants on one platform, wherever they are produced. All designers can work on it at the same time – on a single server to which they all have virtual access.”

Perspective: Focusing on engineering

As one can see, BOMAG’s electrical engineers and designers have achieved a great deal and are using the digital twin not only for electrical planning, but also for the wire harness designs. This facilitates prototype construction and also makes it much easier to make changes and add new options to current products. What does the future hold and what do the managers plan? Sascha Michalski: “We will be standardising and automating even more. We are heading down this path together and are in regular contact with the experts from Eplan to talk about it: What are the next steps? Where is there room for improvement? Where can we bring in more automation? Modules like Eplan Smart Wiring and Pro Panel could help us here. And the topic of ‘cross-site data exchange’ will also continue to keep us busy – again in collaboration with Eplan.”